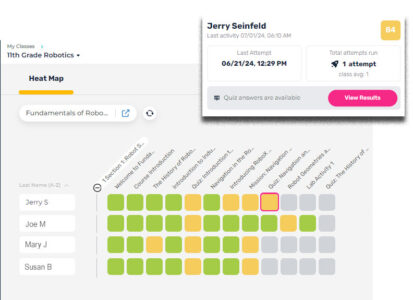

Fundamentals of Robotics with RoboX is an online curriculum that provides students the fundamental skills needed to operate, maintain, program and test robotic systems using virtual robotics. The course uses the RoboX gamified, realistic, 3D robotic simulation software, that allows students to experience operation and programming skills through a variety of simulated robotic missions.

RoboX can be expanded to classes that use real robot hardware as well with the included exercises and labs.

Course Outline

This section introduces the foundational elements of robotics, focusing on how robots are built, function, and are applied in industry. You’ll learn the history and evolution of robotics, explore industrial robot components, and navigate the RoboX simulator. By the end, you’ll understand how robots operate and feel confident using RoboX, setting the stage for the rest of the course.

- Video: Welcome to Fundamentals of Robotics

- Lesson: Course Introduction

- Lesson: The History of Robotics

- Lesson: Introduction to Industrial Robotics

- Quiz: Introduction to Industrial Robots

- Lesson: Navigation in the RoboX Simulator

- Video: Introducing RoboX Missions

- Mission: Navigation and the Simulation Camera

- Quiz: Navigation and the Simulation Camera

- Lesson: Robot Geometries and Your Robot

- Lab Activity: Getting Started with Your Robotic Arm

- Quiz: Robot Geometries

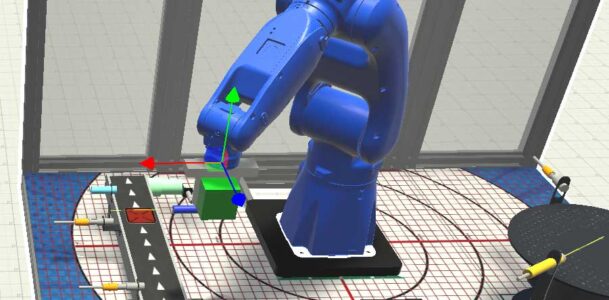

Coordinate systems are essential for programming precise robot movements. Here, you’ll explore the Joint, Cartesian, Tool, and User coordinate systems while learning to “jog” a robot in multiple ways. RoboX missions and lab activities will reinforce these concepts and build your ability to manually control robots with accuracy and flexibility.

- Video: Robot Coordinate Systems

- Lesson: Robot Coordinate Systems

- Mission: Joint Coordinates

- Mission: Cartesian Coordinates

- Quiz: Coordinate Systems

- Mission: Lead-By-Nose

- Lab Activity: Coordinate Systems

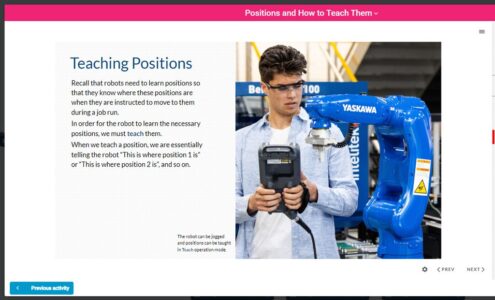

This section explores the teaching of robot positions and the programming of motion sequences. Learn to register positions, plan paths, and use the RoboX robot to execute realistic industrial tasks. You’ll also be introduced to programming basics and key concepts like position variables, block programming, and playback modes.

- Lesson: Motion Sequences

- Quiz: Positions and Motion Sequences

- Lesson: Positions and How to Teach Them

- Lesson: Introduction to Programming

- Quiz: Introduction to Programming

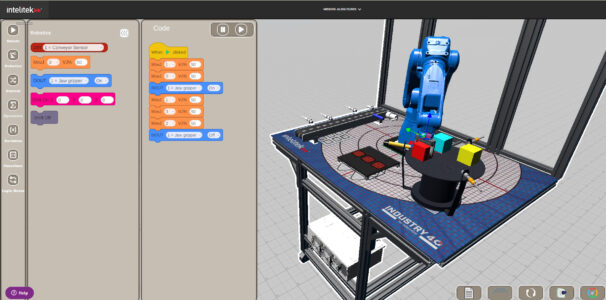

- Mission: Introduction to Block Programming

- Mission: Introduction to Block Programming 2

- Mission: Introduction to Block Programming 3

- Mission: Positions and Motion Planning

- Mission: Positions and Motion Planning 2

- Lab Activity: Motion Programming 1

- Lab Activity: Motion Programming 2

Pick-and-place operations are central to industrial material handling applications. In this section, you’ll learn how to operate your robot’s gripper and perform basic pick-and-place tasks. You’ll also investigate gripper types, gripper powering systems, and gripper states. In the RoboX missions, you will begin to develop skills for preparing precise and efficient material handling programs.

- Video: Introducing the Gripper

- Lesson: Operating the Gripper

- Quiz: The Gripper

- Mission: The Pneumatic Gripper

- Lesson: Pick-and-Place

- Mission: Programming with the Gripper

- Mission: The Vacuum Gripper

- Lab Activity: The Gripper

Interpolation focuses on programming a robot’s motion between points. You’ll study different motion types—linear, circular, and more—through RoboX missions and hands-on labs. By the end of this section, you’ll understand how to optimize motion paths and speeds, which is a critical skill for real- world applications like welding and assembly.

- Video: Interpolation

- Lesson: Interpolation Types

- Mission: Programming with MOVL

- Quiz: Interpolation

- Mission: The Vacuum Gripper 2

- Lab Activity: Linear Interpolation

- Lab Activity: Circular Interpolation

- Lab Activity: Path Training

This section emphasizes advanced material handling techniques. You’ll explore programming loops, rotation strategies, and stacking operations, and apply these concepts in RoboX missions and labs. By mastering these skills, you’ll be ready to handle complex tasks like cube stacking, alignment, and rotation with precision.

- Video: Introduction to Material Handling

- Mission: Programming with the Gripper 2

- Lesson: Program Cycles and Forever Loops

- Mission: Program Cycle

- Lab Activity: Programming Loops

- Lesson: Options for Rotating

- Mission: A Rotated Target

- Lesson: Stacking

- Mission: Stack Cubes

- Mission: Align Cubes

- Lab Activity: User Coordinate Systems

This final section consolidates your skills with advanced labs on optimization, interference areas, and material handling challenges. These hands-on activities simulate real-world and imagined scenarios, preparing you to apply everything you’ve learned about industrial robotic arms.

Lab Activity: Optimization and Position Level

Lab Activity: Interference Areas

Lab Activity: Material Handling Challenges

NIMS is a nonprofit formed in 1995 to develop and maintain a globally competitive workforce. Their mission is to help organizations improve overall performance by teaching them how to train and validate training with practical experiences that reflect what individuals and teams will face on the job. NIMS has a stakeholder base of over 6,000 companies in partnership with major industry trade association Robot Operators are the skilled technicians who operate and maintain workcells on a production or operations floor. Having the skillset qualifies students to work in any automated industrial environment. NIMS Robotics operators credentials validate a candidate can utilize robotics equipment to perform application-specific tasks while following applicable safety regulations. Intelitek Fundamentals of Robotics Curriculum and labs cover all the knowledge and provide the hands on experience to complete the NIMS credentials for Robot Operator

NIMS Smart Credentials

About NIMS

NIMS Robotic Operator Credentials