Industry 4.0 Curriculum

Smart manufacturing and Industry 4.0 are a huge shift in how industrial processes work. While the core skills are similar, the introduction of new advanced technologies like smart sensors, the extensive use of communications, advanced integration, and modern software and computing have changed manufacturing.

Intelitek Industry 4.0 Curriculum offer learners expertise in the broader ecosystem as well as new Industry 4.0 technology innovations.

Curriculum for Industry 4.0:

- Introductory to advanced curriculum focused on Industry 4.0 concepts and technology

- Provide detailed knowledge of how Industry 4.0 will affect roles and work environments

- Students learn the benefits of smart maintenance, operational efficiency, remote monitoring and flexible mass production

Intelitek Smart Series curriculum augment our advanced manufacturing programs introducing students to Industry 4.0 theories and technology

- Instructor led or self paced learning programs include instructor aids, class management, assessments and hands-on labs

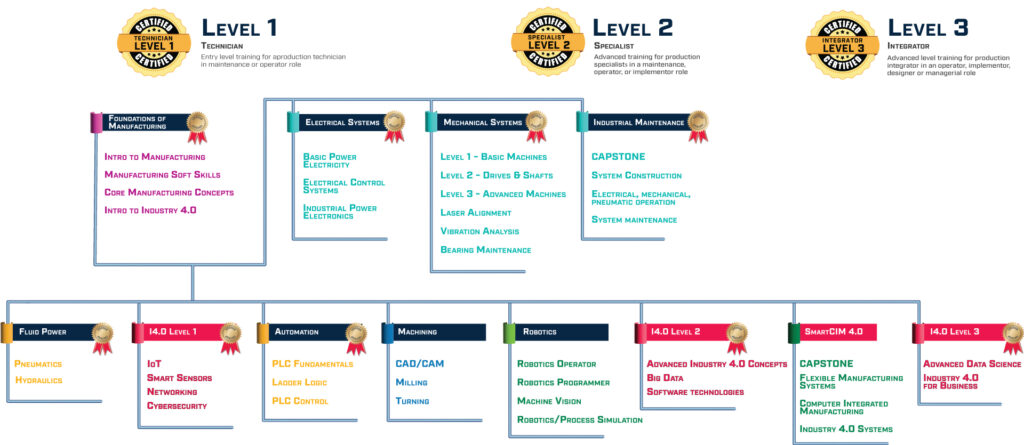

- Tiered program for technician, operator and integrator level students

- Specialized Industry 4.0 curriculum augment existing advanced manufacturing training programs

- Aligned to Industry 4.0 Certification

Level 1

Introduction to Industry 4.0 offers a window into the impact of the Fourth Industrial Revolution and its accompanying technologies on the modern manufacturing industry. Using examples and analogies from real-world enterprises, the course explores Industry 4.0 concepts, processes, and technologies, and testifies to how these components interconnect together in order to grow the manufacturing industry of the future.

Course Outline

- What is Industry 4.0?

- Technologies that Drive Industry 4.0

- Challenges for Industry 4.0

- Quality 4.0

- Supply Chain 4.0

- Data Standardization

- Internet and Ethernet

- The Internet of Things

- Industrial Control Systems and IIoT

- Big Data

- Automation & Software Technologies

- VR, AR, and AI

- Maintenance 4.0

- Flexible Production

- Maturity Models for Industry 4.0

Introduction to the Internet of Things and Connectivity focuses on the vast network of smart sensors and devices and their impact on the manufacturing world. This course also explores topics related to the interconnection of IoT and industrial devices, such as SCADA systems, cloud computing, edge computing, and machine vision systems.

Course Outline

- Introduction to Sensors, Smart Sensors, and Actuators

- Introduction to PLCs

- IoT and IIoT

- IIoT Opportunities, Risks, and Challenges

- The Potential of Connectivity in IIoT

- How a Sensor Connects to the Cloud

- Introduction to Edge Computing

- SCADA Systems

- Vision Systems

- Architecture of Smart Manufacturing Systems

- Introduction to Communication Protocols

- Tracking Methods

Introduction to Networking and Cybersecurity is an in-depth look at communication exchange in modern industry, from the Internet to the Industrial Internet of Things (IIoT) and Cloud technologies. The course covers key networking principles, and concentrates on the structure and importance of industry-focused cybersecurity exploring threats that manufacturing entities have to contend with and combat.

Course Outline

- IP Networking Basics

- Communication Protocols

- Cloud Computing

- Components of the Manufacturing Network

- Securing Digital Manufacturing Operations

- Cyber Threats & Basic Cybersecurity Practices

- Essential Cyber System Technologies

- Malware & Malware Protection

- Identifying Cyber Attacks & Cyber Breach Response

- IIoT Cybersecurity Basics

- Cloud Cybersecurity Basics

- Cybersecurity Resources

The curriculum explores the modern world of data, including its collection, processing, management, visualization, and ultimately, its uses. The course also delves into big data implementation in cutting-edge manufacturing, and machine learning, predictive analytics, modeling, simulation, improvement of processes and progress indicators.

Course Outline

- Introduction to Big Data

- Characteristics of Big Data and Dimensions of Scalability

- Intelligent Decision Making and Getting Value Out of Big Data

- Data Collection and Management

- Algorithms, Computing, and Descriptive Statistics

- Data Analysis

- Visualization of Data

- Predictive Analytics and Modeling

- Machine Learning

- Introduction to KPIs

- Improving KPIs with Big Data

- Database Fundamentals

- Data Warehousing

- Data Mining

- Cloud Computing for Big Data

- Data-Driven Innovation

Level 2

This course explores how technologies interact with each other and with industrial components to create efficient, productive, and profitable enterprises. Emphasizing use cases, the course investigates digital threads, flexible manufacturing, and asset tracking.

Prerequisite: Intro to Industry 4.0 (lvl 1)

Course Outline

- Digital Factory Tour

- The Digital Thread

- VR and AR in Manufacturing

- Smart Sensors in Manufacturing

- Cyberphysical Systems

- Flexible Manufacturing Systems

- Additive Manufacturing

- Maintenance 4.0

- Inventory and Asset Management

Advanced IIoT and Connectivity for Industry 4.0 focuses on the vast network of smart sensors and devices that is the Internet of Things (IoT) and how such systems are integrated and deployed in today’s industrial environments.Building on the introductory course, Advanced IIoT and Connectivity delves deeper into the workings of industrial operation technologies (OT) and information technologies (IT).

Prerequisite: Intro to IoT and Connectivity (lvl 1)

Course Outline

- Smart Sensors – Part 1

- Smart Sensors – Part 2

- PLC Functions and Applications

- Machine to Machine (M2M) Communication

- Cloud Connectivity – Part 1

- Cloud Connectivity – Part 2

- SCADA Systems – Part 1

- SCADA Systems – Part 2

- Implementing IoT

- Design Modularity in Smart Factories

- Industrial IoT Reference Architecture (IIRA)

- IoT Protocols and Standards – Part 1

- IoT Protocols and Standards – Part 2

- Material Identification – Part 1

- Material Identification – Part 2

- Driving Manufacturing with IIoT

The course explores cybersecurity concepts and investigates the ways that cyberattacks can occur and be prevented in industrial control systems and IIoT networks.

Prerequisite: Intro to Cybersecurity (lvl 1)

Course Outline

- Cybermonitoring Tools

- Firewalls

- Switch Protection

- Antivirus Installation and Configuration

- Managing Ports and Services

- Cryptography

- IoT Vulnerabilities, Attacks, and Countermeasures

- Secure Design of IoT Devices

- Operational Security Lifecycle

- Identity and Access Management Solutions for the IoT &

- Mitigating IoT Privacy Concerns

- IoT Compliance Monitoring

- Cloud Security for IIoT

- Incident Response and Forensic Analysis

- Performing steps to Establish Persistence in a Compromised network or Device

This course explores the different types of software that are essential for a production company’s success in the automated commercial and industrial landscape.

Course Outline

- Software Technology Overview

- APS – Advanced supply chain & planning systems

- MES – Manufacturing Execution Systems

- ERP – Enterprise Resource Planning systems

- Scheduling Software

- Cryptography

- System Visualization Tools for VR, AR and Digital Twinning

- Quality Control Software

- Artificial Intelligence Software

- Business Intelligence Tools

- Data Modeling Software

Level 3

Data collection, storage, and analytics play a massive role in the manufacturing industry. The vast amounts of data generated by production processes and the potential involved in the use of this data creates substantial economic opportunities for businesses that take advantage of them. Advanced Data Science for Industry 4.0 explores how the proper use of data can help manufacturing enterprises significantly improve their bottom line.

Course Outline

- Data Warehousing

- Data Mining

- KPIs of Big Data

- One Metric That Matters

- Data Driven Innovation

- AI, Machine Learning, and Deep Learning

- Course Project

High level look at the Industry 4.0 Smart manufacturing in industry and the trends and use cases for technology

Course Outline

- Industry 4.0 – The super infrastructure for the future of manufacturing (market trends)

- Requirements for a factory to be Industry 4.0 (technology trends)

- Industry 4.0 and Business processes (Flexible Mass Production) Real time business processes

- Enhanced customer experience

- Competitive industrial production

- Customized mass production

- Maintaining production (improved reliability/quality)

A look at industry 4.0 from the business perspective. The course will look at the benefits and justifications for manufacturing.

Course Outline

- Outcomes of Industry 4.0

- Customer satisfaction

- Information transparency

- Customized mass production

- Intelligent decision making

- Asset management

Use cases examples (Case Studies)

- Business with industry 4.0

- Business 4.0 (business efficiency)

- Supply chain 4.0

- Quality 4.0

- Maintenance 4.0