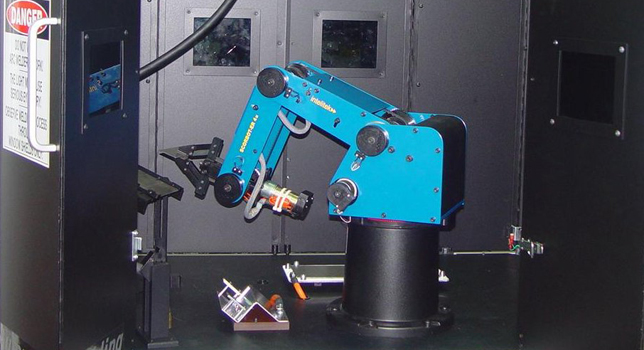

This turnkey automated welding station gives students training and skills in production welding methods, robotic programming and control.

Using RoboCell software students safely perform entire welding processes in 3D simulation before executing actual automated welding applications.

Students learn to overcome common welding problems, such as thermal deformation, by adjusting welding technique. Students also learn to improve weld quality by optimizing important welding parameters such as wire feed rate, robot speed, inert gas shield and voltage.

Safety is an integral part of the system. The robotic workbench is housed in a fire retardant metal booth with filter-plated windows for UV and eye protection. Opening a booth door automatically halts the welding operation. Pressing either of two emergency buttons immediately halts both robotic and welding operations.

Package includes:

– SCORBOT-ER 4u robot and controller

– RoboCell for Controller-USB software (includes SCORBASE)

– MIG welder

– Welding booth

– Parts feeder

– Welding gun holder

– Gripper adapter for welding gun

– Welding jigs

SCORBOT-ER 4u: mechanical arm; Controller-USB; cables

Welding booth

Floor mounted, fully enclosed, fire-retardant

Extruded aluminum frame with sheet-metal walls and doors

Metal workbench surface

Metal service shelf

Dimensions: L=1.2 m, W=0.8 m, H=1.8 m (L=47″, W=31″, H=70″)

Additional components for automated welding

MIG welder; gas metal arc welding (GMAW)

Welding gun holder

Gripper adapter for welding gun

Automated tool exchange enables alternating use of robot gripper and welding torch

Parts feeder

Jigs for T-joints, butt-joints and other welding applications; jigs are electrically isolated from the welding bench

Metal templates for holding parts for welding applications

Raw materials and parts for welding application

Software

SCORBASE for Controller-USB

RoboCell for Controller-USB

Software includes 3D simulated automated welding application

Safety features

Filter-plated windows (Shade 10) for UV and eye protection

Complies with ANSI radiation standard Z87.1-1989

Welding operations stop automatically whenever any booth door is opened

2 emergency stop buttons halt robotic and welding operations

Sample applications demonstrate proper welding and safety techniques

Inert gas tank

Exhaust venting system

Computer workbench: extruded aluminum frame; formica tabletop; 800 mm x 600 mm