Over the past three decades, Intelitek has established itself as the leader in educational CNC (Computer Numeric Control) machines, with over 13,000 CNC machines installed in educational institutions across the world.

Our latest line of Bench and Pro series CNC machines push the envelope for ease-of-use and affordability. Coupled with interactive online e-learning courses with fully-integrated web-based simulations of our machines, we offer an unmatched solution for CNC technology training.

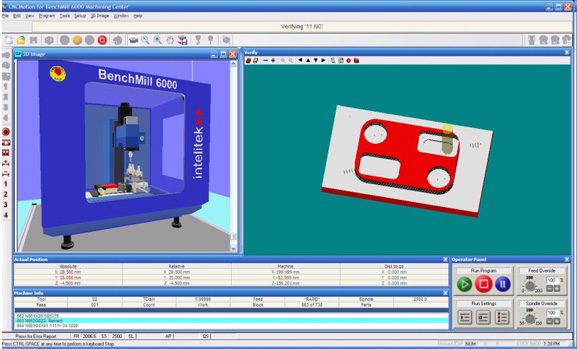

BenchMill 6×00 CNC Milling Center

The BenchMill 6×00 is a PC-based benchtop CNC machining center enabling robust CNC and advanced manufacturing instruction!

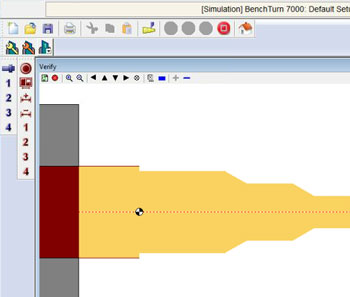

BenchTurn 7×00 CNC Turning Center

A versatile PC-based benchtop CNC turning center designed for robust CNC and advanced manufacturing instruction!

ProMill 8000 CNC Machining Center

The ProMill 8000 is a 3-axis, PC-based mill with an optional 4th rotary axis, featuring AC servo motors!

ProTurn 9000 CNC Turning Center

A versatile PC-based CNC lathe with powerful AC servo motors

CNC Milling Technology with BenchMill 6×00 – Virtual

Introduces students to the fundamentals of CNC milling by working with interactive, simulated machining applications.

CNC Turning Technology with BenchTurn 7000 – Virtual

Introduces students to the fundamentals of CNC turning with project-based activities with fully integrated simulations of the BenchMill 7000.

CNC Milling Technology with ProMill 8000 – Virtual

Introduces students to the fundamentals of CNC milling by working with interactive, simulated machining applications.

CNC Turning Technology with ProTurn 9000 – Virtual

Introduces students to the fundamentals of CNC by working with the ProTurn 9000 CNC machine.

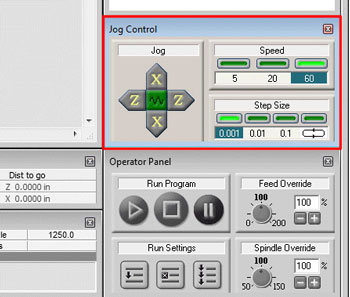

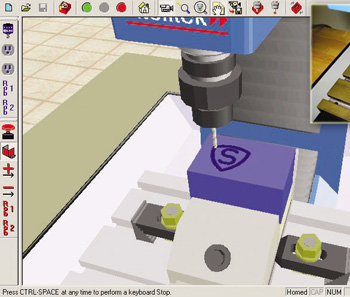

CNCBase®

A CNC control software package that provides an intuitive tool for programming and operating Intelitekֲ´s CNC machines

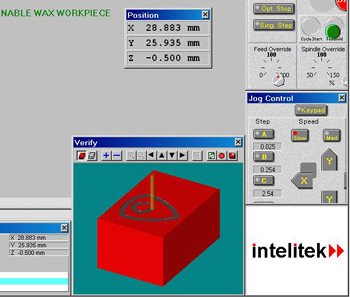

CNCMotion®

CNC Motion provides dynamic simulation and graphic tracking of intelitek´s CNC mills and lathes.

FANUC™ 21i Emulator

For CNCBase & CNCMotion

The FANUC emulator replicates the FANUC 21i CNC controller and its subset, the FANUC 16i and 18i controllers

CNC Milling Technology with BenchMill 6×00 – Lab and Virtual

Hours of Instruction: 15

Course Outline:

Activity 1: Introduction and Safety

Activity 2: CNCBase Control Software

Activity 3: Mounting the Workpiece

Activity 4: Tooling

Activity 5: Reference Positions

Activity 6: Verifying a Program

Activity 7: Running a Program

Activity 8: Fundamentals of NC Programming

Activity 9: Programming the House

Activity 10: Machining Project #1

Activity 11: Arc Programming

Activity 12: Programming the Star – Project #2

Activity 13: Machining Project #2

Activity 14: Programming Your Initials – Project #3

Activity 15: Final Project

CNC Turning Technology with BenchTurn 7000 – Lab and Virtual

Hours of Instruction: 15

Course Outline:

Activity 1: Introduction and Safety

Activity 2: CNCBase Control Software

Activity 3: Mounting the Workpiece

Activity 4: Tooling

Activity 5: Reference Positions

Activity 6: Verifying a Program

Activity 7: Running a Program

Activity 8: Fundamentals of NC Programming

Activity 9: Programming the House

Activity 10: Machining Project #1

Activity 11: Arc Programming

Activity 12: Programming the Star – Project #2

Activity 13: Machining Project #2

Activity 14: Programming Your Initials – Project #3

Activity 15: Final Project

CNC Milling Technology with ProMill 8000 – Lab and Virtual

Hours of Instruction: 15

Course Outline:

Activity 1: Introduction and Safety

Activity 2: CNCMotion Control Software

Activity 3: Mounting the Workpiece

Activity 4: Tooling

Activity 5: Reference Positions

Activity 6: Verifying a Program

Activity 7: Running a Program

Activity 8: Fundamentals of NC Programming

Activity 9: Programming the House

Activity 10: Machining Project #1

Activity 11: Arc Programming

Activity 12: Programming the Star – Project #2

Activity 13: Machining Project #2

Activity 14: Programming Your Initials – Project #3

Activity 15: Final Project

CNC Turning Technology with ProTurn 9000 – Lab and Virtual

Hours of Instruction: 15

Course Outline:

Activity 1: Introduction and Safety

Activity 2: CNCBase Control Software

Activity 3: Securing the Workpiece

Activity 4: Tooling

Activity 5: Reference Positions

Activity 6: Verifying a Program

Activity 7: Running a Program

Activity 8: Fundamentals of NC Programming

Activity 9: Programming a Taper

Activity 10: Machining Project #1

Activity 11: Arc Programming

Activity 12: Programming Project #2

Activity 13: Machining Project #2

Activity 14: Project #3

Activity 15: Final Project

CNC Programming with FANUC™ Controller for BenchMill 6×00, BenchTurn 7000, ProMill 8000, ProTurn 9000

Hours of Instruction: 6

Course Outline:

Activity 1: Installation

Activity 2: Navigation the Fanuc Screen

Activity 3: Controlling the Display

Activity 4: Operating the Virtual Machine Using Fanuc Control

Activity 5: Verifying a Program

Activity 6: Operating the Virtual Machine using the 3D Image Screen

Activity 7: Defining Tools

Activity 8: Setting the Workpiece Origin

Activity 9: Entering a New Program

Activity 10: Using MDI (Manual Data Interface)

Activity 11: Manual Machining

Activity 12: Using Incremental Jogging

Activity 13: Using the Manual Pulse Generator

Activity 14: Importing an NC Program into Fanuc

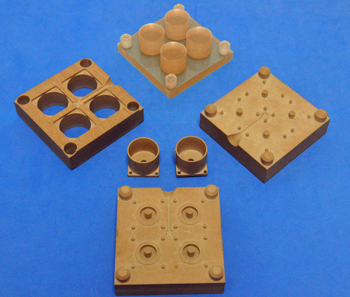

Advanced Manufacturing Technology (AMT) Competition – 4-Cavity Mold

SkillsUSA Competitions: 4-Cavity Mold

By means of this SkillsUSA competition, students demonstrate the skills needed for employment in the automated manufacturing field

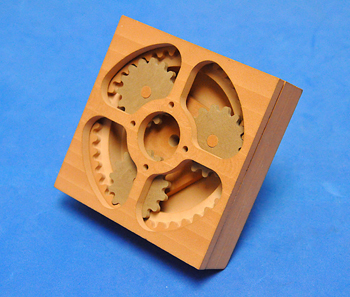

Advanced Manufacturing Technology (AMT) Competition – Planetary Gearbox

SkillsUSA Competitions: Planetary Gearbox

By means of this SkillsUSA competition, students demonstrate the skills needed for employment in the automated manufacturing field