CNC Turning Technology introduces students to the fundamentals of CNC (Computer Numerical Control) by working with a variety of simulated machining applications with the virtual ProTurn 9000 – 100% online, on-demand!

By means of project-based learning, students gain experience with the entire design and production process. Starting with developing and editing programs, students complete projects to learn proper machine set up, cutting tool selection, tool path simulation and turning center operation. Students design solutions for industrial CNC applications emphasizing optimized programming, precision and productivity.

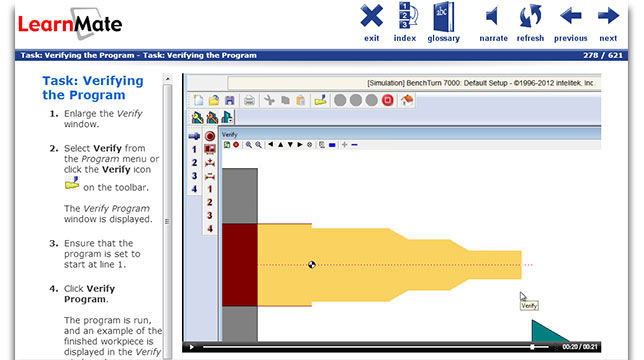

This virtual CNC course allows students to explore topics through engaging animations and simulations of the same classroom hardware used in the lab version! The simulated machining center features the same an intuitive software interface and conforms to industrial EIA, ISO, Fanuc and G&M code standards.

Included

Order #16-3143

Includes:

LearnMate® Content: CNC Turning Technology with ProTurn 9000 (Virtual Format)

CNCMotion® CNC simulation software

Sign, CNC Turning Technology

Activity 1: Introduction and Safety

Activity 2: CNCMotion Control Software

Activity 3: Securing the Workpiece

Activity 4: Tooling

Activity 5: Reference Positions

Activity 6: Verifying a Program

Activity 7: Running a Program

Activity 8: Fundamentals of NC Programming

Activity 9: Programming a Taper

Activity 10: Machining Project #1

Activity 11: Arc Programming

Activity 12: Programming Project #2

Activity 13: Machining Project #2

Activity 14: Project #3

Activity 15: Final Project

CNC TurningTechnology with ProTurn 9000 is also available in Lab format!

The Lab course features the ProTurn 9000 Lathe and related lab hardware for robust hands-on instruction. Choose between Lab and Virtual courses based on your program objectives and budget, or implement both together for a truly scalable program!