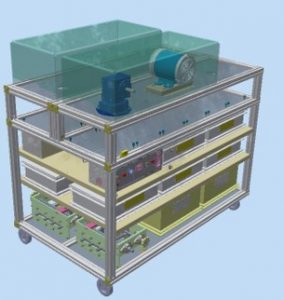

The JobMaster® Mechanical Training Program is a robust, modular and stand-alone CTE solution providing comprehensive training in mechanical power transmission for students who will integrate into industry jobs. JobMaster® Mechanical Systems teaches the specialized skills required for today’s industrial technicians. The skills-based training is built with real-world industry in mind and is structured to deliver learning via job tasks in formats that students will see when they work in actual plants. The trainer features industrial-strength components housed in a modular and mobile framework with a customized modular storage system. Designed for ease of use, the trainer can be installed on the optional mobile base or any suitable workbench for single sided, or dual sided use, and can be customized to include the training components needed for your course structure.

Flexible, Modular, Mobile Platform

The solution features six levels of mechanical elements including the basic and advanced machines, shafts, bearings, belt drives, chain drives, gear drives, couplings, brakes & speed reducers, laser

alignment, vibration analysis and bearing maintenance. The JobMaster Mechanical Training series provides a superior blended learning solution for training to prepare students for jobs in manufacturing and industrial maintenance by combining industrial grade components with engaging e-learning curriculum. With JobMaster, you can be sure your training program will deliver the skills needed for success in automated manufacturing careers!

- Level 1 – Machines/Shafts/Bearings – JM-MBL1-000x

- Level 2 – Belts/Chains/Couplings – JM-MBL2-000x

- Level 3 – Gears/Brakes/Speed Reducers – JM-MBL3-000x

- Level 4 – Laser Alignment – JM-MBL4-0000

- Level 5 – Vibration Analysis – JM-MBL5-0000

- Level 6 – Bearing Maintenance Kit – JM-MBL6-000x

System Components

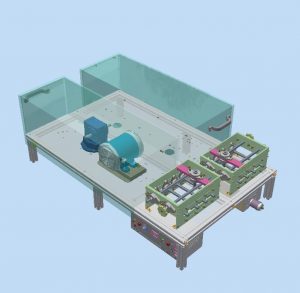

Mechanical Training Working Surface (included with Level 1)

Standalone working surface setup suitable for use with Intelitek Mobile Bench or other workbenches

Single or Double sided configuration

Dimensions: 52” x 32” x 8” (LxWxH) 1310mm x 800mm x 203mm

Lab Hardware Kits (included in level bundles)

Hardware kits with industrial grade training components:

- Coupling Kit

- Shaft, Bearing Kit

- Sheave, Pulley, Sprocket Kit

- Motor/Speed Reducer Kit

- Gears Kit

- C-Brake/Speed Reducer Kit

- Gear Box Kit

- Laser Alignment Kit

- Vibration Analysis Kit

- Bearing Kit (standalone)

Mobile Bench for Mechanical Training (optional add on)

Mobile Bench for Elec/Mech Series – 00-1800-0001 (Optional)

Shelf Set for Mobile Bench – 10-1800-0001 (Optional)

Dimensions: 52” x 32” x 32” (LxWxH) 1310mm x 800mm x 800mm

Features:

Integrated with Intelitek curriculum, the system offers in-depth theory and workplace training. The courses from Intelitek prepare students to work with actual equipment they will find in the field. Using standard mountings and flexible modules, the training can be configured, dismantled and reconfigured regularly. The equipment is designed tor ease of mobility to allow flexible classrooms and easy storage. The modular and flexible design and optional mobile bench can facilitate one large classroom or multiple smaller classes simultaneously.

- Modular design

- Single or Double sided configuration

- Independent groups on single workbench

- Supports identical or different setups

- Mobile with everything onboard for easy transportation between classrooms

- Rugged, industrial design

- Standard mounting hardware

- Mobile Bench available

- Same mobile bench used for JobMaster Electrical Series

Levels of Modular Training

Level 1

Mechanical Training Level 1 Bundle includes the tabletop working surface for mechanical training and curriculum for Basic Machines, Machine Statics & Dynamics, Shafts & Keys, Bearings.

The single bench setup for two students or double bench setup for four students includes all the hardware and curriculum for the four (4) learning modules.

Skills Curriculum Included

ME01 – Basic Machines

• Measurement

• Torque

• Work

• Power

• Horsepower

• Friction

• Velocity

• Acceleration

• Mass and Inertia

ME02 Machine Statics & Dynamics

• Identify Stress, Strain and Combined Stresses

• Identify Material Fatigue and Fatigue Stress Points

• Identify Fatigue Failure and Failure Modes

ME03 – Machine Shafts & Keys

• Measuring and Verifying Shafts

• Demonstrating Shaft Expansion Principles

• Measuring Eccentricity and Shaft Runout

• Demonstrating Shaft Key Principles

• Preparing a Key from Keystock

• Shaft Troubleshooting and Failure Analysis

ME04 – Bearings

• Identifying Bearing Types

• Reading Bearing Dimensions

• Mounting Bearing Housings

• Reading a Tolerance Chart

• Bearing Troubleshooting and Failure Analysis

Level 2

Mechanical Training Level 2 Bundle continues from the Level 1 training and includes training for Belt Drives, Chain Drives, and Machine Shaft Coupling.

The add on set for two students or four students includes all the hardware and curriculum for the three (3) learning modules.

Prereqisites: JobMaster Mechanical Training Level 1 is required

Skills Curriculum Included

ME05 – Belt Drives

• Demonstrating Belt Drive Ratio Principles

• Installing Belt Drives

• Aligning a Belt Drive

• Belt Tensioning

• Installing Adjustable Speed Sheaves

• Installing Positive Drive Systems

• Belt Troubleshooting and Maintenance

ME06 – Chain Drives

• Demonstrating Roller Chain & Sprocket Principles

• Sizing Chain

• Installing and Aligning Sprockets

• Installing Chain Drives

• Adjusting Slack

• Troubleshooting and Maintenance

ME07 – Machine Shaft Couplings

• Identifying Shaft Couplings

• Correcting Soft Foot

• Aligning Shafts

• Aligning Rims and Faces

• Connecting Chain Couplings

• Connecting Universal Joints

Level 3

Mechanical Training Level 3 Bundle continues from the Level 2 training and includes training for Gear Drives, Machine Speed Reducers and Electric Brakes.

The add on set for two students or four students includes all the required hardware and curriculum for the three (3) learning modules. Single bench setup for two students

Prereqisites: JobMaster Mechanical Training Level 1 and Level 2 is required

Skills Curriculum Included

ME08 – Gear Drives

• Demonstrating Gear Measurement Principles

• Installing a Worm Gear Drive

• Installing a Spur Gear Drive

• Measuring Backlash

• Installing a Helical Gear Drive

• Installing a Bevel Gear Drive

• Maintaining and Troubleshooting Gear Drives

ME09 – Machine Speed Reducers

• Demonstrating Basic Speed Reducer Principles

• Selecting a Speed Reducer

• Maintaining & Troubleshooting Speed Reducers

ME10 – Electric Brakes

• Operating Electric Brakes

• Installing Electric Brakes

• Maintaining & Troubleshooting Electric brakes

Level 4

Laser Alignment

The Laser Alignment Training package is an optional supplement to the JobMaster Mechanical Training Series. This option adds laser tools for both shaft and belt alignment along with all the hardware needed to deliver comprehensive instruction in all aspects of Laser Alignment.

Prereqisites: JobMaster Mechanical Training Level 1 and Level 2 is required

Skills Curriculum Included

ME11: Laser Alignment

• Aligning a Belt Drive

• Aligning a Coupling

• Correcting for Soft Foot

• Filling Out an Alignment Report

Level 5

Vibration Analysis

The Vibration Analysis Training package is an optional supplement to the JobMaster Mechanical Training Series. This option adds a digital vibration analyzer, shafts, rotors and other industrial- grade components to deliver comprehensive instruction in all aspects of vibration analysis

Prereqisites: JobMaster Mechanical Training Level 1 and Level 2 is required

Skills Curriculum Included

ME12: Vibration Analysis

• Reading a Vibration Severity Chart

• Filling Out a Maintenance Log

• Measuring the Vibration of a Motor

• Measuring the Axis and Location of Vibration

• Measuring Shaft Misalignment

• Troubleshooting Misaligned Shaft Vibration

• Measuring Coupling Vibration

• Troubleshooting Bent Shaft Vibration

• Troubleshooting Defective Shaft

• Component Vibration

• Troubleshooting Resonant Vibration

• Demonstrating Vibration Source Principles

Level 6

Bearing Maintenance

The Bearing Maintenance Training is a standalone mobile training kit for installing, removing and servicing plain and roller bearings. Students learn the principles of proper bearing service and work with a bearing packer, bearing pullers, an arbor press, grease gun and various bearing types.

Skills Curriculum Included

ME13: Bearing Service

• Identifying Anti-Friction Bearings

• Identifying Plain Bearings

• Using an Arbor Press

• Using a Bearing Puller

• Installing and Removing Bushings

• Using a Cone Heater

• Loading a Grease Gun

• Greasing a Pillow Block

• Hand Packing a Bearing

• Using a Bearing Packer

• Demonstrating Bearing Seal Principles

• Performing Bearing Failure Analysis