Our CIM systems are modular and flexible solutions for educating and training students in the principles and technologies of computer integrated manufacturing.

Computer Integrated Manufacturing (CIM) system has several key components: an automated storage and retrieval system (ASRS), at least one automated workstation such as CNC machining, a continuous-loop conveyor, a central management control station, a TCP/IP communication network, and OpenCIM software.

Additional workstations can be added at any time for executing a variety of automated tasks, such as laser engraving, hydraulic and pneumatic device operation, process control, and quality control inspection.

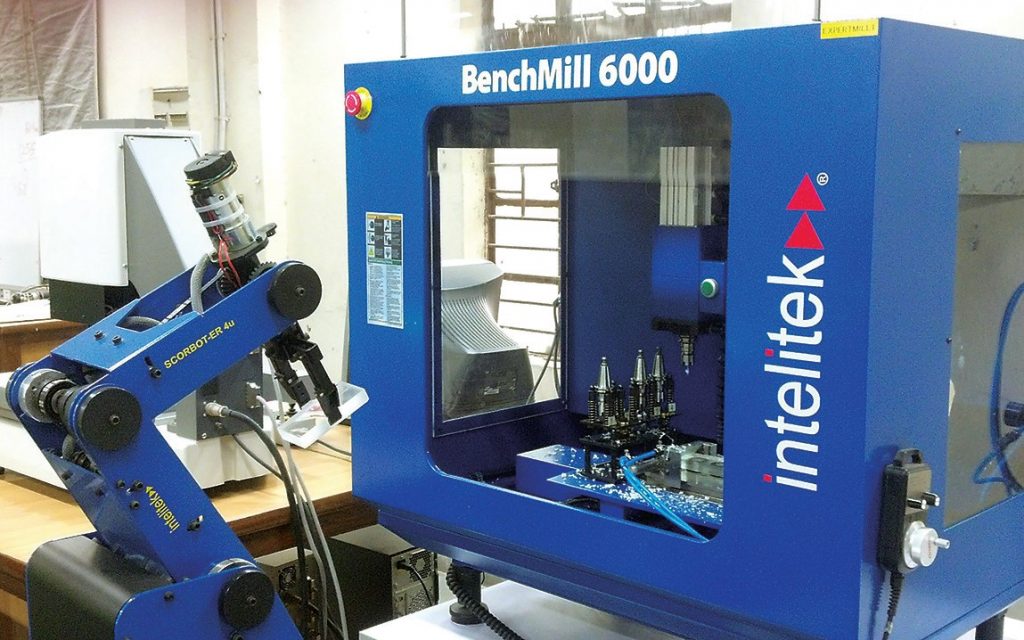

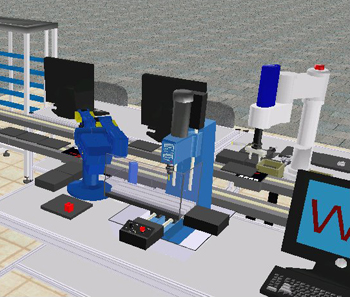

Machine Tending Stations

A Machine Tending Station can be used as a stand-alone workcell, or integrated within a CIM system. The robot tends the CNC machine and performs other part manipulation and/or assembly tasks.

When used in a CIM system, the robot loads and unloads parts to and from the CIM conveyor. The robot is mounted on a linear slidebase for mobility and larger work area.

Any of the MTS stations can be provided as a standalone FMS.

Storage Station

The ASRS storage station is a floor-mounted or a table top automated storage and retrieval (ASRS) system designed for educational use.

The system’s dedicated Cartesian robot transfers parts between storage cells and conveyor pallets stopped at the ASRS station.

The robot is controlled by Controller-USB and by a dedicated ASRS software module in the OpenCIM software. An optional hand-held teach

pendant can also be used for direct control of the ASRS.

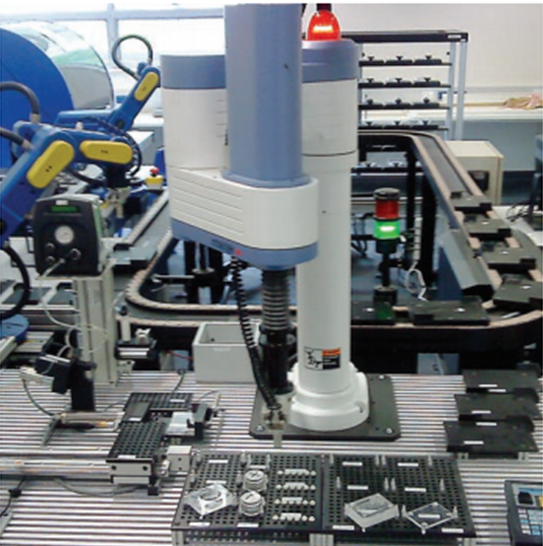

Assembly & Quality Control Station

The assembly and QC station is equipped with a variety of assembly and quality control devices as well as with local storage devices.

This turnkey station gives students training and skills in assembly, quality control, robotic programming and automated manufacturing systems.

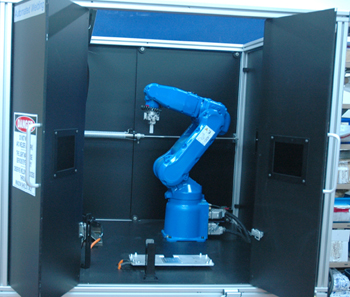

Welding Station

This turnkey automated welding station gives students training and skills in production welding methods, robotic programming and control.

Using RoboCell software students safely perform entire welding processes in 3D simulation before executing actual automated welding applications.

Students learn to overcome common welding problems, such as thermal deformation, by adjusting welding technique. Students also learn to improve weld quality by optimizing important welding parameters such as wire feed rate, robot speed, inert gas shield and voltage.

Additional CIM Components

Conveyor

The conveyor frame is constructed of extruded, black anodized aluminum. A double flexible-chain moves in the inner and outer rails and moves the load (pallets) by friction.

Due to the modular concept of CIM systems, a large variety and lengths and shapes of conveyors can be created.

Programmable Logic Controller (PLC) Station

The PLC (Programmable Logic Controller) can control and monitor the flow of pallets on the conveyor with the help of sensors and actuators that are build into the stop stations.

Various PLC types (Siemens, Omron, Allen-Bradley) and field bus systems (digital I/O,

PROFIBUS, ASI bus) are supported.

Pallet Tracking Station

The stop station allows the PLC to control and monitor the flow of pallets on the conveyor with the help of sensors and actuators that are built into the stop stations.

Stop stations for various PLC types (Siemens, Omron, Allen-Bradley) and field bus systems (digital I/O, PROFIBUS, ASI bus) are supported.

Linear Slide Base (LSB)

The PLC (Programmable Logic Controller) can control and monitor the flow of pallets on the conveyor with the help of sensors and actuators that are build into the stop stations.

Various PLC types (Siemens, Omron, Allen-Bradley) and field bus systems (digital I/O,

PROFIBUS, ASI bus) are supported.

Gravity Parts Feeder

A gravity-operated feeder for delivering parts to a robotic materials handling or machine tending operation. A microswitch sensor detects the presence or absence of parts and communicates with the robot controller by means of I/O connections.

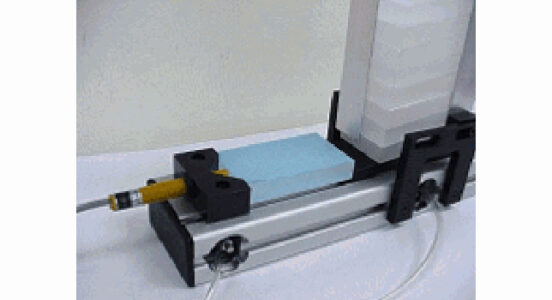

Pneumatic Parts Feeder

A pneumatically operated parts feeder with sensor for detecting presence of objects. There are two options available to choose from:

This feeder supplies square parts and is adjustable for part size.

Management Station

The management station is a central control console with one or more computers where the OpenCIM software and/or other manufacturing and configuration software is set up and run. The Management station is often used as a learning station with access to the online learning provide by Intelitek with the system.

The OpenCIM software is a computer-integrated systems management solution that contains all the elements found in fully-automated facilities.

Shop floor management controls the operation of all the elements of automated factory.

Administrative software connects the shop floor management to the production facility’s Enterprise Resource Planning (ERP).

The OpenCIM software contains an ERP package which breaks down customer orders to analyze bill of materials, check availability of raw materials, produce vendor’s purchase order and schedule production based on expected lead times.

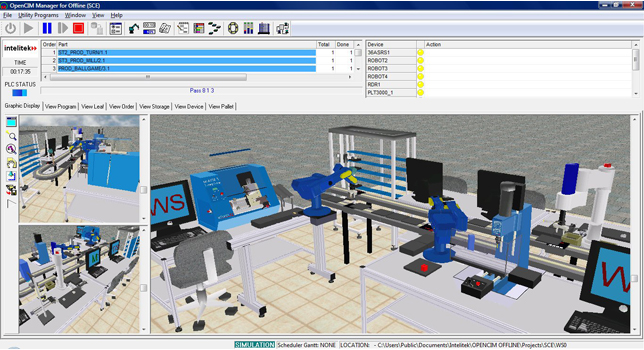

OpenCIM

OpenCIM is a complete software package for the operation, control and simulation of CIM systems.

The OpenCIM software is a computer-integrated systems management solution that contains all the elements found in fully-automated facilities.

- Shop floor management controls the operation of all the elements of automated factory.

- Administrative software connects the shop floor management to the production facility’s Enterprise Resource Planning (ERP).

- The ERP package (part of OpenCIM) breaks down customer orders to analyze bill of materials, check availability of raw materials, produce vendor’s purchase order and schedule production based on expected lead times.

Curriculum

Computer Integrated Manufacturing (CIM) curriculum introduces students to automation and industrial applications of Computer Integrated manufacturing applications. The curriculum addresses the systems approach to manufacturing and how to manage, maintain and optimize a production process.