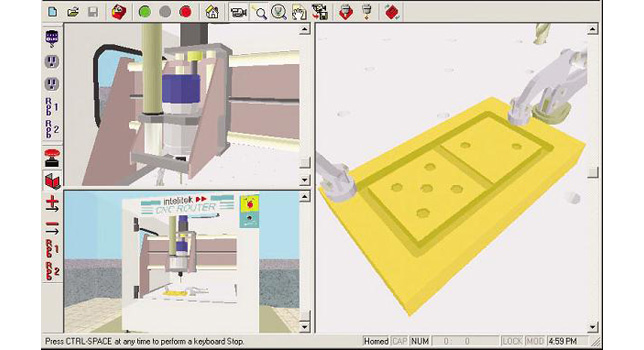

CNCMotion integrates interactive 3D simulation with CNCBase machine control software for dynamic simulation and graphic tracking of Intelitek’s CNC mills and lathes.

CNCMotion simulates the entire machining process in real time-accurately reflecting the movement of machine components and tools, and the form of raw materials changing into finished parts.

The virtual machines in CNCMotion respond to errors and environmental conditions in the same way as safeguards on real machines prevent injury and damage. Safety measures include halting NC program execution upon impact or axis limit, and warnings of unsafe hardware conditions (e.g., safety shield open, tool missing, tool impact on the cross-slide or holding device).

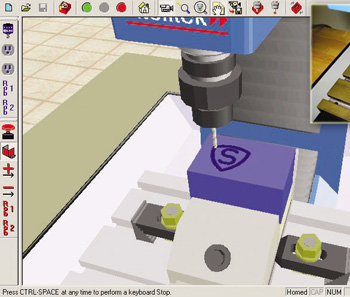

As a powerful visualization tool, the software enables testing and debugging of programming, as well as full machine setup, prior to actual CNC machining and turning.

The simulation includes fixturing with all available Intelitek hardware options. For example, simulated stock holding options for the Super proLIGHT 1000 machining center include a 52-piece hold-down set, machinist vise, low profile clamping kit and two air vises. Simulated tooling options for the Super proLIGHT 1000 include flat end mills, ball end mills and drills, along with R-8 tooling, quick-change tooling, and automatic tool changing (ATC).

The realistically simulated CNC machines give students and machine operators valuable experience before they begin working in a CNC workshop.

Standard Features

Graphic setup

- Interactive graphic setup enables customization of machines, including various machine tools and fixtures.

- Definitions and properties of clamps, vises and chucks; fixtures can be defined as pneumatically or manually operated.

- Definitions and tool offsets for up to 20 predefined and user-defined tools.

- Definition of manual tool holders/posts, or automatic tool changer/tool turret.

- Definitions and properties of workpieces: material, color and size.

- During setup all definitions are verified by software to ensure compatibility with actual hardware and physical environment.

- CNCMotion simulates every tooling option available on our machines onscreen control of the same options and accessories you use with the actual machine.

Dynamic 3D simulation

- Dynamic simulation and graphic tracking of CNC mill and lathe during manual operation and NC program execution.

- Simulates cross-slide, spindle and tool movements.

- Simulates in real time the changing form of workpiece during the entire machining process, including milling, turning, engraving and routing.

- Reflects the behavior of machines in real-world conditions, including axis limits, impact, automatic and emergency stops, and shield engaged stops.

- Enables experimentation with virtual parts of different shapes, sizes and materials, such as wax, brass, wood and aluminum.

- Point and click on screen to move the tool for workpiece origin definition.

- Full control of machining parameters during simulation, including feed rate and spindle speed.

- Display of current tool coordinates and state of hardware components (e.g., on/off, open/closed).

- Various viewing and display controls; e.g., zoom, rotate, pan, drag, redirect.

- 3D tool path verification during machining.

- Can simultaneously display three different 3D views of the CNC machine.

- Graphic tool path verification is a standard feature with all of our CNC control software. CNCMotion takes simulation to the next level. Beyond displaying the tool path on the part, CNCMotion simulates all aspects of machine operation on-screen in 3-D; a virtual machine!

Programming and control

- Fully integrated with CNCBase control software, an intuitive tool for programming and operating CNC machines.

- Available Fanuc emulator replicates standard industry control. Switch between Intelitek and Fanuc control with the click of the mouse.

Milling Options

- All standard-size tooling

- 4” precision vice

- Single axis air vise

- Dual axis air vise

- Clamping kit

- 4-station ATC for BenchMill 6000 or ProMill 8000

- 12-tool carousel ATC for ProMill 8000

- Rotary worktable (4th axis) with 3-jaw chuck

- Coolant system

- Lubrication system

- Automatic shield opener

Turning Options

- All standard-size tooling

- 3-jaw chuck

- Air chuck

- 4-station automatic tool turret

- Tailstock

- Coolant system

- Lubrication system

- Automatic shield opener

Data Sheet

Click here to download a PDF data sheet.

DOWNLOAD