By 2030, the predicted shortage of people in STEM fields will be 4.4 million at an annual cost of $450 billion to the US economy. Even today, manufacturing, logistics, and back-end retail have difficulty filling open jobs. First, there is a profound labor shortage; and second, employers see a significant skills gap between the skills students exit school with and the skills they’re looking for.

This skills gap between worker training at high schools and community college and Career and Technical Education (CTE) levels and Industry 4.0 are being driven by the new technology incorporated into manufacturing. Technological advancement provides an opportunity for small to medium manufacturing to again be part of US industry. With the right equipment and a trained workforce, manufacturing can once again become a significant contributor to the US economy.

Manufacturers are pushing schools to develop more advanced and complex training for students to prepare them for highly technical careers in manufacturing and related jobs. Industry is changing quickly, particularly in the areas of automation. Workers are no longer packing boxes individually, but programming and fixing computerized production equipment. Industry 4.0 is disrupting factories worldwide with new technology that enhances industrial processes. Manufacturers are asking for upskilled workers with experience in areas like integration, virtualization, simulation, and data analytics.

And it’s not just manufacturing. The Internet of Things (IoT) is also driving change. It integrates sensing, computation, control and networking into physical objects and infrastructure. These cyber-physical systems are extremely important in the fields of transportation and energy, health care and medicine, and the environment and sustainability.

Education 4.0 for Industry 4.0

The shift in language from “vocational school” to CTE, STEM, and robotics is raising awareness of the importance of technical education. Every student should have the opportunity to study computer coding and robotics if they’re interested in this type of skilled technical career. But schools and colleges need to improve the pipeline of future workers by embracing workforce development as a valued part of the curriculum.

Both high schools and community colleges are in an ideal position to expand and upgrade their CTE courses. With the trend toward personalized learning, we have more tools at our disposal to offer students flexible courses and even hands-on training for job certifications where they acquire marketable skills of interest to industrial employers.

Industry 4.0 is focused on smart technology, artificial intelligence, and robotics. This means that teaching students about these types of emerging technologies is critical to their abilities to move directly from school to the workforce. Adding development of complex problem solving, critical thinking, and communication skills puts more tools in students’ toolkits.

As it’s clear that high schools and community colleges must upgrade their programs to meet demands for a new workforce, here are some suggestions to improve the quality and capacity of CTE programs:

- Expand the curriculum by adding new courses in multiple STEM disciplines

- Introduce expanded training for emerging technology

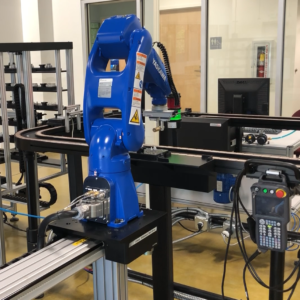

- Acquire industrial equipment for real-time application of skills

- Create more career pathways and certifications

- Divide curriculum into flexible online learning and in-person, hands-on training

- Expand analytics to provide every student with data management skills

It is clear that Industry 4.0 is a business and economic imperative that extends beyond manufacturing to many other STEM fields that incorporate emerging technology, automation, and other technical skills. If we are to move beyond the Industry 4.0 challenges we have today, we must upgrade our CTE programs and expand the pipeline for highly skilled workers for manufacturing jobs.