The world robotics market continues to boom and while the old adage that robots will replace humans has long since been debunked, the truth is that robotics changes the face of manufacturing and so schools teaching manufacturing at all levels need to adapt.

Mechatronics programs, industrial maintenance programs, manufacturing programs and many other more specialized education paths that focus on preparing students for work in industry need to turn out more robotics savvy technicians, specialists and integrators.

While the robotics market in China was down 1% in 2018, the US market grew to a new peak with 22% growth. There is still huge potential for growth as the USA is still only number eight in the robotic use worldwide (density of 217 robots per 10,000 employees) [1]. Robotics is also expanding into more areas – for the first time, shipments to non-automotive industry grew faster than automotive – 41% growth [2].

The concept of the smart factory, or Industry 4.0, is a major driver of this change in the US market. Smart manufacturing enables efficient, cost effective manufacturing and on-demand supply that can compete with low income countries that have captured much of the manufacturing in the last few decades. US manufacturing is growing, and jobs are returning, however, these are different jobs.

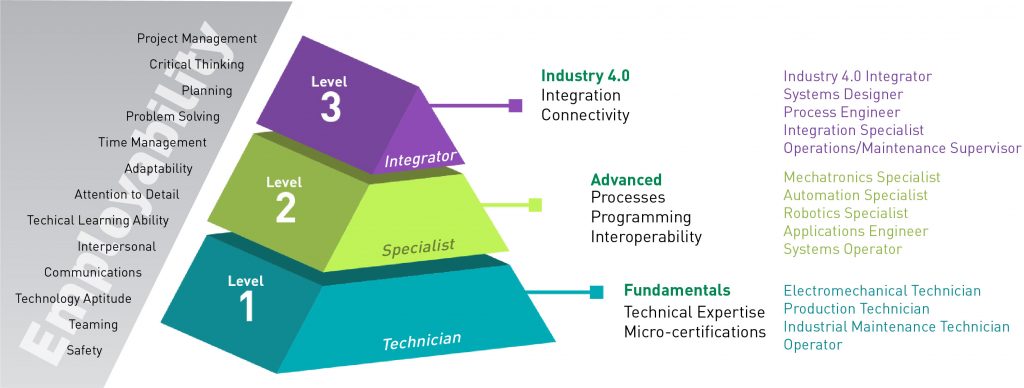

ARM (Advanced Manufacturing in Robotics) is one industry groups that has recently created a blueprint of skills or competencies companies are looking for in employees in this new manufacturing realm. From the level of technician in support, installation and maintenance roles, through the level of specialist in operation and programming roles, to the level of integrator in the design and optimization of manufacturing systems, the emphasis is on multi-disciplinary knowledge, communications and integration. Training needs to focus not only on individual skills and competencies, but also on the breadth of knowledge, the employability skills needed in a modern environment, and the integration or automation of multi-functional environments.

This blueprint is the framework for industry certifications. Credentials employers can validate when evaluating potential candidates.

Intelitek has developed a new Industry 4.0 Certification that integrates this concept and offers schools at the secondary and post-secondary level options to take their traditional programs to the next level. The comprehensive iCert4.0 is flexible and can be easily integrated into existing programs (Read more here). The industry support for this initiative ensures colleges can build their capabilities with the support of local companies.

Industry 4.0 is not a new technology like earlier industrial revolutions, Industry 4.0 is about using the most modern versions of technologies and integrating them to work better together. Networking, communications, IIoT, autonomous and collaborative robots, and big data are the technology glue that create a more efficient manufacturing environment and CTE/Manufacturing programs need to ensure they are preparing their students to fit in to this new world.

[1] https://ifr.org/ifr-press-releases/news/robot-investment-reaches-record-16.5-billion-usd

[2] https://www.robotics.org/content-detail.cfm/Industrial-Robotics-News/First-Half-of-2019-Shows-Continued-Growth-in-Robotic-Sales/content_id/8314

Industry 4.0 is not a new technology like earlier industrial revolutions, Industry 4.0 is about using the most modern versions of technologies and integrating them to work better together. Networking, communications, IIoT, autonomous and collaborative robots, and big data are the technology glue that create a more efficient manufacturing environment and CTE/Manufacturing programs need to ensure they are preparing their students to fit in to this new world.

[1] https://ifr.org/ifr-press-releases/news/robot-investment-reaches-record-16.5-billion-usd

[2] https://www.robotics.org/content-detail.cfm/Industrial-Robotics-News/First-Half-of-2019-Shows-Continued-Growth-in-Robotic-Sales/content_id/8314

Industry 4.0 is not a new technology like earlier industrial revolutions, Industry 4.0 is about using the most modern versions of technologies and integrating them to work better together. Networking, communications, IIoT, autonomous and collaborative robots, and big data are the technology glue that create a more efficient manufacturing environment and CTE/Manufacturing programs need to ensure they are preparing their students to fit in to this new world.

[1] https://ifr.org/ifr-press-releases/news/robot-investment-reaches-record-16.5-billion-usd

[2] https://www.robotics.org/content-detail.cfm/Industrial-Robotics-News/First-Half-of-2019-Shows-Continued-Growth-in-Robotic-Sales/content_id/8314

Industry 4.0 is not a new technology like earlier industrial revolutions, Industry 4.0 is about using the most modern versions of technologies and integrating them to work better together. Networking, communications, IIoT, autonomous and collaborative robots, and big data are the technology glue that create a more efficient manufacturing environment and CTE/Manufacturing programs need to ensure they are preparing their students to fit in to this new world.

[1] https://ifr.org/ifr-press-releases/news/robot-investment-reaches-record-16.5-billion-usd

[2] https://www.robotics.org/content-detail.cfm/Industrial-Robotics-News/First-Half-of-2019-Shows-Continued-Growth-in-Robotic-Sales/content_id/8314