Mechanical Measurement and Quality Control gives students a solid foundation of knowledge and skill in performing measurements and calculations. Students learn to use precision measurement tools, such as steel rule, tape measure, protractor, micrometer, height gauge, various calipers and dial indicators.

Students learn how to collect data on a sample and calculate the mean, median and standard deviation. They also learn how these concepts relate to statistical sampling, tolerance and quality control. The training package includes statistical process control (SPC) software that allows students to collect and display measurement data in a graph or spreadsheet.

Students gain proficiency in reading mechanical drawings, in selecting the proper tools for inspecting parts and in preparing quality control/inspection reports.

Mechanical Measurement and Quality Control includes everything you need for successful blended learning.

- Through LearnMate, essential resources are provided for both students and teachers.

- Students are always one click away from glossaries and help files available on each page.

- Teachers have instant access to handouts, tips and detailed activity instructions.

Mechanical Measurement and Quality Control is part of the Foundations of Advanced Manufacturing series, which teaches the introductory skills essential for success in advanced manufacturing careers.

Foundations of Advanced Manufacturing is ideal for any engineering or automated manufacturing program, providing a thorough and engaging element of STEM (Science, Technology, Engineering and Mathematics) education.

- Getting Started

- Accuracy, Precision and Measurement Tools

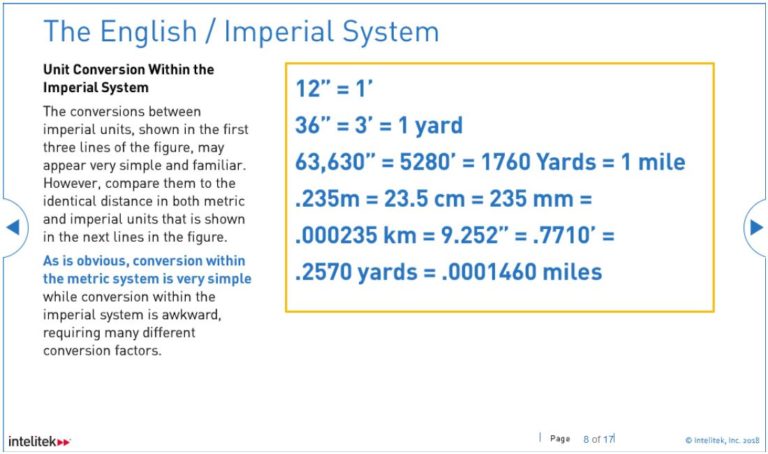

- Units of Measurement and Conversion

- Fractions, Decimals, and Rounding

- Scaled Measurement Tools

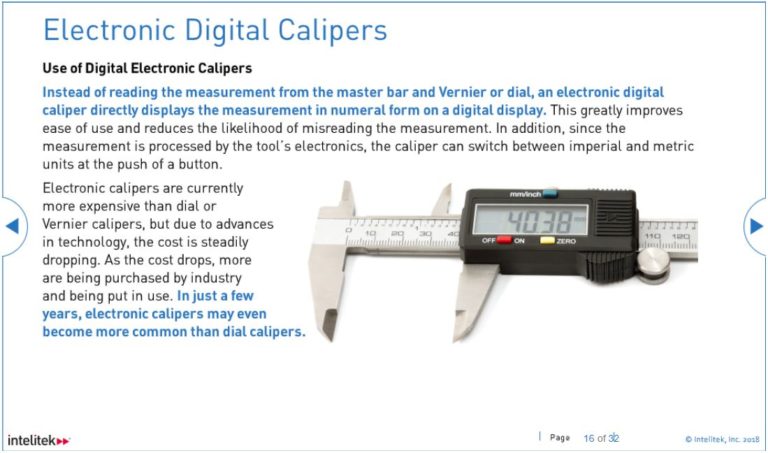

- Vernier, Dial, and Digital Calipers

- Micrometers

- Height Gauges and Dial Indicators

- Fixed Gauges

- Transfer Measurement Tools

- Statistical Analysis

- Statistical Process Control

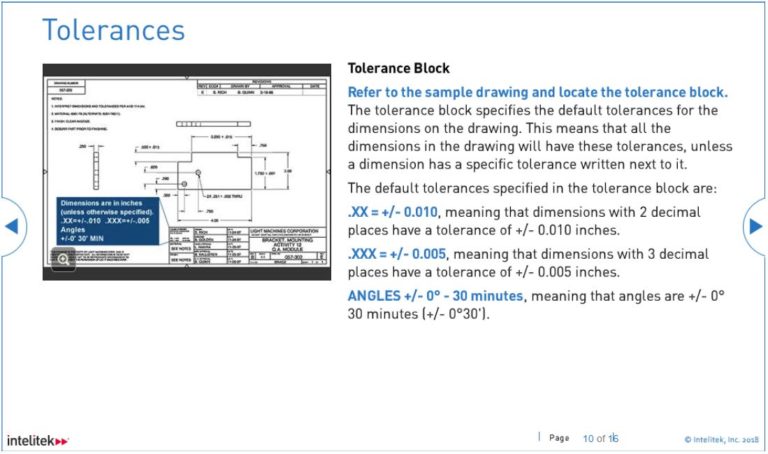

- Nominal Dimensions and Tolerance

- Parts Inspection and Inspection Reports

- Conclusion

Optional Hardware Kit Available

Mechanical Measurement and Quality Control is also available with all the hardware you need for hands on lab activities.

Measuring devices

– 300 mm steel ruler

– 6″”/150 mm steel ruler

– 16’/5 m tape measure

– 1″”/25 mm micrometer

– 6″”/150 mm dial caliper

– 6″”/150 mm electronic digital caliper

– 6″”/150 mm Vernier caliper

– 4″”/100 mm inside caliper, not graduated

– 4″”/100 mm outside caliper, not graduated

– Dial indicator (with attachment to enable mounting on height gauge)

– 6″”/150 mm digital height gauge

– Clamp (to enable mounting of dial indicator on height gauge)

– Protractor

– 5-piece gauge block set

– 11-piece plug gauge set

– Granite surface plate

– Ground slotted angle plate

– Angle plate

– 12″” wooden ruler (USA only)

– Feeler gauge set (6 leaves) (USA only)

Additional components

– Tool storage case for all instruments

– PVC tube assembly (capped pipe) for lab experiments

– Aluminum bracket for lab experiments

– Millimeter/inch equivalents charts (in Student Book)

– Tool usage educational charts (in Student Book)

– Inch/metric tap drill sizes and decimal equivalents wall chart

– Inch/metric tap drill sizes and decimal equivalents card

– ”Tools and Rules for Precision Measurement” booklet (USA only)

– Cable and adapter

– Statistical process control (SPC) software

This course is a component of the Foundations of Manufacturing series and the Advanced Foundations of Manufacturing series.

The online training can be used individually to augment an existing curriculum program or as a series to provide students fundamental and broad understanding of the manufacturing world.

For more information, contact Intelitek or one of our regional partners.