Integrated engineering program opens up pathways for students

The Applied Technology Center (ATC) at Milford High School in Milford, New Hampshire, is a unique program delivering broad exposure to STEM (science, technology, engineering and mathematics) for students. The ATC program is succeeding in attracting students from many backgrounds and opening up new pathways to opportunities in careers and college.

The 4-year program consists of an introductory course open to freshmen that leads into further courses in Engineering Design and Computer Integrated Manufacturing (CIM). The capstone Advanced Engineering Design course features a self-directed engineering project. Students enrolled at least two semesters qualify for dual credit with the New Hampshire Community College System.

This year the ATC program added LearnMate® e-learning curriculum from Intelitek®, a New Hampshire-based company specializing in solutions for technology education. Educational STEM Solutions, Intelitek’s New England distributor, has provided integral support to bringing the curriculum online. The new curriculum will enable students to access the courses from home, including fully integrated simulations of the design and machining process.

“I saw the ability to design and create whatever you can imagine. I knew I’d be interested”

Frank Xydias, who students call “Mr. X”, teaches the Engineering courses in the ATC program. He believes the e-learning component will bring a new world of advantages: “They can access curriculum anywhere – if there’s a snow day or a student is absent for extended time, they can never miss a beat. They can connect via email and check their grades. It’s a great advantage.”

These new capabilities will even help out on the shop floor.

“I have 17 students at a time, but I don’t have 17 computers or machines,” says Xydias. “Students can use the simulations and check their programs before attempting to run them in the shop. So we have less down time in between on the machines.”

Hear from ATC Students!

Integrating Engineering and Manufacturing

One unique aspect of the program is the robust machine tool offering. The CIM class covers CNC programming and hands-on experience in the machine shop. Xydias and Paul Bois, Precision Machining teacher, have built an effective synergy between the engineering and machining disciplines.

“Paul and I work together,” says Xydias. “We exchange students between classes.”

“It can be a challenge to find an engineer with true machining acumen,” says Rosie Deloge, the Director of Technical Studies for the Milford High School and the ATC. “Applied technology integrates engineering with manufacturing.”

Students with diverse educational interests are attracted to such an integrated program.

“The CIM class is unique,” says Xydias. “A student can enter with three different types of foundation. The student who has had basic programming with the computer science department, a 1st year engineering student and a 1st year machining student – all three of those students can take this class.”

The machining component lends a practical aspect to the concepts students learn in the engineering courses.

“One of the projects the freshman design are chess pieces and some of the designs are really intricate, but can you manufacturer that? They are using irregular numbers, not common fractions. So we teach them to use real world values, regular tolerances – something that can be manufactured. And we talk about the process – how are you going to hold it, will you need any special type of fixture?”

Josh Lepine, a senior in his fourth year in the ATC program, notes the benefits of this approach: “By using the 3-D CAD programs I can see how the part goes together and see if it actually works. Once a design is created I then begin the manufacturing process. It is a great feeling to see your parts come to life.”

Helping Students Discover Interests

Ronny Eichler, currently a senior in the program, was attracted to the program after his 8th-grade class visited on a field trip.

“At first I did not want to make engineering my career,” he says. “It seemed like such a long process to make it to where I would want to be. Then they showed us all the machines and computers and technology that they have here. I saw the ability to design and create whatever you can imagine, which I thought was really cool. I knew I’d be interested.”

“We look for those students that are really passionate about what they do and take on that leadership role,” says Xydias. “Ronny is one of those students. Each year we would give him a little more. He was ready, and he took the lead on his own.”

Ronny soon was assisting other students and helping to teach the CIM class.

“Mr. X and Mr. Bois make an excellent teaching team,” says Ronny. “After my junior year I had more knowledge than I ever thought I would have and I saw engineering as a way of life rather than just a class.”

After graduation, Ronny will use the skills he learned by working on aircraft with the National Guard, earning college credits for the experience. After basic training he intends to enroll in a local college for a dual major in machining and aircraft mechanics.

Joe Albina, another senior in the program, also saw the program change his goals.

“I like working with my hands. I was working towards being a mechanic, probably going to tech school. Being in the class, seeing how you could go from nothing, to a design, to making parts, opened my eyes to what I could do.”

Now Joe plans to major in mechanical engineering. He selected Roger William University – a decision influenced by his experiences in the machining class.

“This school has a machine shop and a welding lab – this was a big factor in my choice.”

Senior Anna Thonis has always been motivated to pursue a career where she could work with environmental issues. The ATC program has introduced her to skills to help her along the way.

“I wasn’t sure if it was the right path for me originally. As a freshman I was signed up for Pre-engineering and I was nervous because there were no other females in the class.”

Now Anna is glad she overcame her initial doubts.

A CAPSTONE PROJECT IN LEAN MANUFACTURING

Milford High School’s Advanced Engineering Design course enables students to choose real-world projects from their choice of engineering fields to explore and discover new interests. Often projects are derived from local businesses or departments within the school.

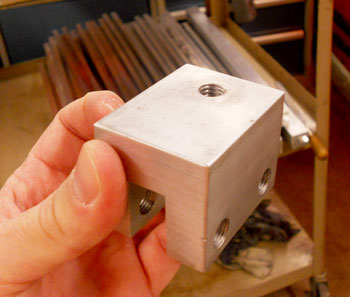

In the 2011 school year, the schools Custodian of the department brought a unique request to the machine shop. The Milford Elementary School needed to install shields on the roof to prevent ice buildup. They needed 870 brackets manufactured to install the shields. The CIM students took on the project.

“It took us two and a half months – it took us a very long time, we had so many students working on it. To make 800 parts on an assembly line when we are used to custom manufacturing was completely different.”

For the 2012 school year, Milford Middle School returned needing more brackets.

“Mr Bois pointed to me and said ‘He will run it’,” says Ronnie.

This time, Ronnie’s experiences had enabled him to bring a new improved approach to the project.

“Earlier in the year I had visited a company -lean manufacturing was their motto. When this project came up I knew I wanted to run it with lean manufacturing; that way it could be faster. Lean manufacturing for this project cut our time in half versus last year. It definitely sped it up and it worked perfect.”

“The program is phenomenal,” she says. “This year I am in Precision Machining and I am the only female in the class and I don’t mind whatsoever. I feel like I am on the same level with all the guys even though sometimes I need a stool to reach the switch on the mill.

“I didn’t know I would like the technical work and machining activities as much as I do. I intend to pursue more of the hands on stuff!”

Anna intends to double-major in environmental engineering and sustainability studies at Rensselaer Polytechnic Institute. She is still formulating her career goals in her mind.

“I don’t know what the career is called – I want to do something in the way of creating new technologies for renewable energy.”

Opening up Multiple Pathways

Rosie Deloge is enthused about the multiple pathways into advanced manufacturing careers made possible by the ATC program. Students have graduated equipped for a four-year engineering programs, community college or direct hire at local industries.

“When a student is accepted as a direct hire in industry, it is just as valuable as acceptance into a degree program,” says Deloge. “That is the goal of career and technical education: preparing students for successful careers.”

The pathway to further education has opened up even more over the past year through Project Running Start, a dual credit program offered by the Community College System of NH.

“Five students will be getting college credit for the class this year – our first year for dual credit in the program,” says Xydias. “We have collaborated with Manchester Community College so that students can receive up to 8 credits into their new mechatronics degree program, and at Nashua Community College, our students can take 7 credits into their machining program.”

Other professional and educational opportunities abound for ATC students.

Hitchiner Manufacturing, the largest employer in Milford, has set up internships and a job shadow program with ATC students, and they mentor the robotics club.

“It is rewarding for students to have that experience working with a real engineer,” says Xydias. “And Hitchiner has hired students.”

A partnership with the Department of Transportation TRAC (Transportation and Civil Engineering) program exposes students to competitive events with schools across New Hampshire.

ATC students also can become are members of the Society of Manufacturing Engineers.

“We are second in the nation to offer this at the high school level,” says Xydias. “This gives our students the valuable opportunity to be members of a national organization with network opportunities and scholarship opportunities.”

“Students enter these programs not knowing what they are looking for and leave it feeling ‘on their feet’ about their future.”

Students have taken notice of the value of these opportunities available through the ATC program. 120 students have enrolled this year – up 20% over last year. Now there is a waiting list to get into the program.

“This is typical of the growth we’ve seen,” says Deloge. “We added robotics engineering with VEX last year and would like to expand our CNC and CIM offerings as well. We need to expand our teaching capacity to expand our offerings!”

Anna appreciates the programs impact on her goals: “It’s a very good program for shaping future plans and helping students know what they are good at and what they can thrive in. I think a lot of students enter these programs not knowing what they are looking for and leave it feeling very ‘on their feet’ about their future.”